Table of Contents

- A Comprehensive Guide to Carpet Yarns .Introduction: The Strategic Importance of Yarn in Carpet Performance

- Decoding Carpet Fiber Fundamentals: Properties and Classifications

- 2.1 Synthetic Fibers: The Pillars of Durability

- 2.2 Natural Fibers: Unmatched Luxury and Perception

- 2.3 Blended Yarns: Engineering the Best of Both Worlds

- Advanced Yarn Constructions and Finishes: Driving Modern Performance

- 3.1 BCF Yarn: The Industry Standard

- 3.2 Engineered Yarns for Specialized Demands

- 3.3 Critical Functional Finishes

- Data-Driven Yarn Selection: Matching Fiber to End Use

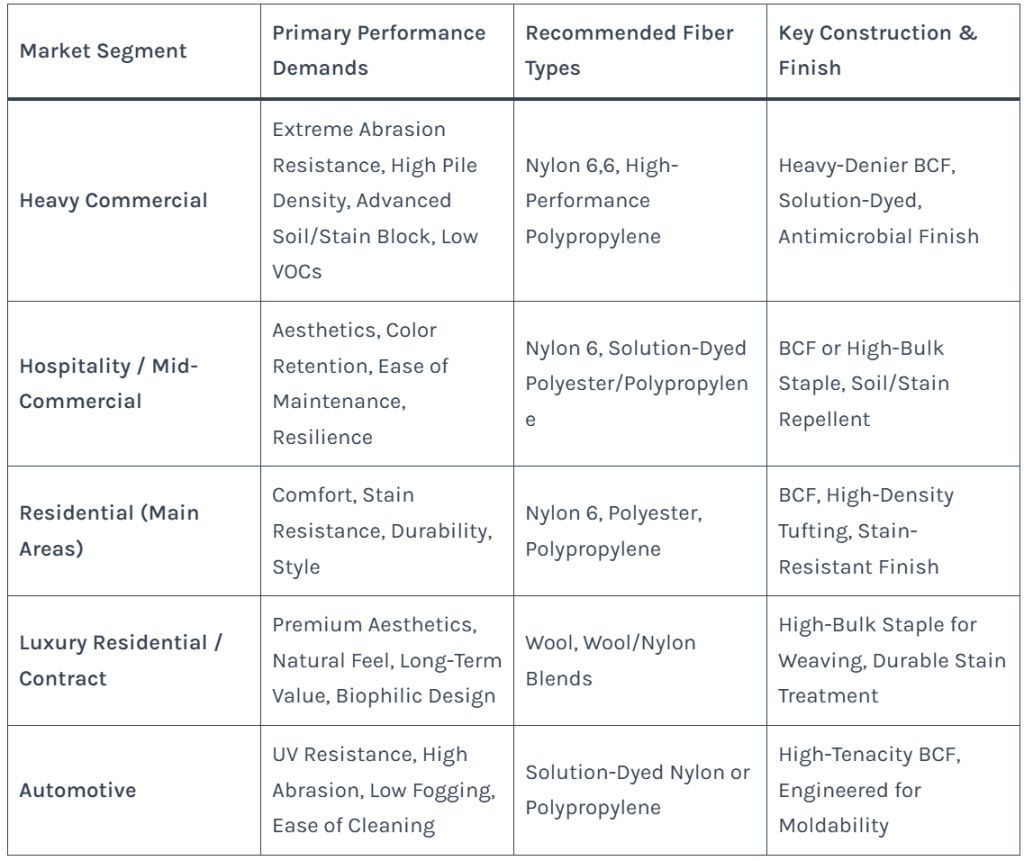

- 4.1 Application Selection Matrix

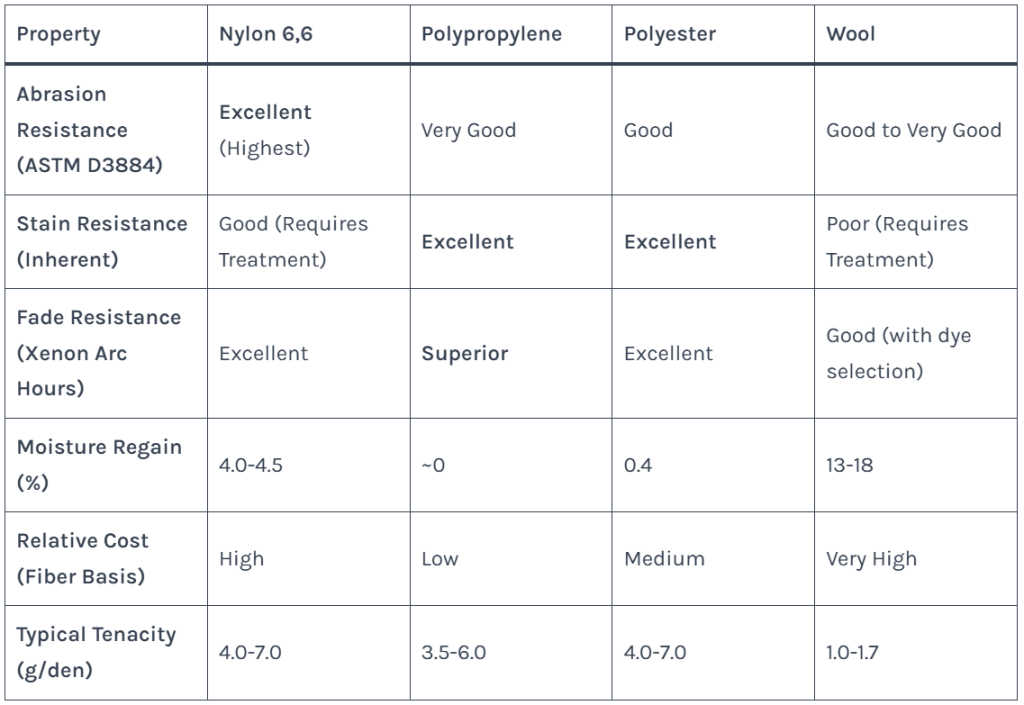

- 4.2 Quantitative Property Comparisons

- Navigating the Global Supply Chain: Trends and Strategic Sourcing

- Partnering for Value: The Role of Technical Yarn Suppliers

- Conclusion: Building Superior Carpets from the Yarn Up

1. Introduction: The Strategic Importance of Yarn in Carpet Performance

In the competitive world of carpet manufacturing, the yarn is not merely a raw material; it is the very foundation of product performance, customer satisfaction, and long-term profitability. For procurement managers, product developers, and production heads, a deep understanding of carpet yarns is crucial to navigating a complex market where durability, aesthetics, and sustainability are non-negotiable.

A carpet’s journey to market success begins long before it’s tufted or woven. It begins with a critical decision made at the fiber and yarn level. This choice determines a staggering 80% or more of the finished carpet’s key characteristics: its resilience against crushing in a hotel corridor, its ability to shed dirt in a family home, its vibrant colorfastness under intense commercial lighting, and even its contribution to indoor environmental quality . An informed selection, therefore, is a primary lever for controlling costs, mitigating performance risks, and delivering superior value to the end consumer.

This guide provides a comprehensive, technical overview of carpet yarns—from the molecular properties of base fibers to the advanced engineering of modern yarn systems. By translating complex polymer science into actionable insights and comparative data, this document serves as a strategic resource for making evidence-based sourcing decisions that will define the quality of your products and the strength of your competitive edge.

2. Decoding Carpet Fiber Fundamentals: Properties and Classifications

All carpet yarns originate from a fundamental choice between synthetic, natural, and blended fiber families. Each family offers a distinct profile of performance attributes, which are quantified and selected based on end-use requirements .

2.1 Synthetic Fibers: The Pillars of Durability

Synthetic fibers dominate the global carpet market, particularly in commercial and high-traffic residential segments, due to their exceptional durability, stain resistance, and cost-effectiveness .

- Nylon (Polyamide): Historically the premium synthetic fiber, known for its outstanding abrasion resistance, tensile strength, and flexibility. Advanced 6,6 nylon grades offer superior soil and stain resistance with treatments. However, its market share is being challenged by more cost-effective alternatives .

- Polypropylene (Olefin): The current volume leader in many sectors. Its primary advantages are excellent resistance to moisture, stains, and fading, coupled with a lower specific gravity, offering more fiber per pound. Polypropylene is inherently static-resistant and is the primary fiber used in bulk continuous filament (BCF) production. Industry trends show its application proportion is growing .

- Polyester (PET): Prized for its exceptional color clarity, luxurious hand, and inherent stain resistance. Developments in modified polyester have significantly improved its durability and resilience, making it a strong contender in the mid-to-high-end residential market.

- Acrylic: Often marketed as a “synthetic wool” for its softness and wool-like aesthetics. It exhibits good bulk and colorfastness and has applications in both tufted and woven carpets, sometimes in blends .

2.2 Natural Fibers: Unmatched Luxury and Perception

Natural fibers command the luxury segment, driven by their unique aesthetics and long-standing reputation for quality .

- Wool: The quintessential luxury fiber. Wool fibers possess a natural crimp that provides superior resilience, soil-hiding ability, and flame retardance. Its natural luster and dye affinity result in deep, rich colors. Wool carpets are known for their durability over decades, justifying the premium price. Classification systems define categories such as “Pure Wool” (≥95%) and “Wool Blend” (≥20%) to inform buyers .

- Others (Silk, Jute, Sisal): While wool is paramount, silk is used in ultra-high-end, decorative hand-made pieces. Jute is almost exclusively used as a backing material rather than face fiber, while sisal and other plant fibers are popular in specialized area rugs for their textural aesthetics .

2.3 Blended Yarns: Engineering the Best of Both Worlds

Strategic blending is a powerful tool for optimizing performance and cost. A common and effective blend is Wool/Nylon, where 70-80% wool is combined with 20-30% nylon. This blend boosts the durability and abrasion resistance of wool while retaining its majority aesthetic and comfort properties . Similarly, blends of synthetic fibers, such as polypropylene with acrylic or viscose, are developed to enhance the hand feel, dyeing properties, or bulk of cost-effective primary fibers .

3. Advanced Yarn Constructions and Finishes: Driving Modern Performance

The value of the fiber is unlocked and amplified through advanced yarn manufacturing technologies.

3.1 BCF Yarn: The Industry Standard

Bulk Continuous Filament (BCF) technology is the backbone of modern tufted carpet production . Unlike spun yarns made from short staple fibers, BCF yarns consist of continuous filaments that are twisted, textured, and heatset together. This process creates:

- Superior Durability: No fiber ends are exposed to wear, significantly reducing pilling and fuzzing.

- Defined Aesthetics: Can be engineered for specific luster levels (bright, semi-dull, dull) and texture.

- Process Efficiency: High-speed production of consistent, high-tenacity yarns directly for tufting.

3.2 Engineered Yarns for Specialized Demands

- Solution-Dyed Yarns: Pigment is added to the polymer melt before extrusion, making the color an intrinsic part of the fiber. This results in exceptional colorfastness (exceeding 4-5 on the AATCC Gray Scale for light and ozone) and superior stain resistance, ideal for commercial and outdoor applications.

- High-Bulk Staple Yarns: Often used in woven carpets like Wilton or Axminster, these yarns are engineered through bi-component fiber technology or special texturing to provide greater loft, coverage, and a luxuriously soft hand.

3.3 Critical Functional Finishes

Applied at the yarn or carpet stage, finishes are essential for performance.

- Stain & Soil Resistance: Fluorochemical or hydrocarbon-based repellents form a protective barrier around fibers. Commercial carpets often feature advanced anti-soil treatments that prevent oily dirt from adhering.

- Static Control: Conductive fibers (like carbon-infused filaments) or topical antistatic treatments are integrated, especially in commercial-grade carpets for office environments, to control static discharge below 3.0 kV.

- Antimicrobial Treatments: Protect against odor-causing bacteria, mold, and mildew, extending carpet life and supporting indoor air quality.

4. Data-Driven Yarn Selection: Matching Fiber to End Use

Selecting the right yarn is a calculated decision based on quantified performance needs.

Table 1: Application-Based Yarn Selection Matrix

Table 2: Quantitative Comparison of Primary Carpet Yarn Fibers

5. Navigating the Global Supply Chain: Trends and Strategic Sourcing

The global carpet yarn supply chain is characterized by consolidation and technological specialization. Large, integrated players like those in China and North America dominate BCF production, while regions with a heritage in textiles offer specialized capabilities in wool processing and high-end weaving yarns .

Key sourcing considerations include:

- Vertical Integration vs. Specialization: Suppliers like glyarn demonstrate the value of a focused, technical approach. Unlike commodity traders, glyarn operates with deep vertical integration in specific yarn technologies, such as advanced BCF spinning. This control allows for unmatched consistency, shorter lead times for custom orders, and direct technical collaboration, which is invaluable for solving production challenges or co-developing new products.

- Sustainability as a Specification: Demand is rising for yarns made from recycled content (e.g., post-consumer PET), bio-based polymers, and fibers with Cradle to Cradle or EPD (Environmental Product Declaration) certifications. Sourcing decisions increasingly hinge on these credentials.

- Total Cost of Ownership (TCO): The most cost-effective yarn is not always the cheapest per kilogram. Factors such as dye yield, processing efficiency (fewer breaks in tufting), coverage (lower density needed for required performance), and longevity must be factored into the TCO calculation.

6. Partnering for Value: The Role of Technical Yarn Suppliers

In today’s market, a yarn supplier should be a value-adding partner, not just a vendor. The most strategic relationships are built on:

- Technical Problem-Solving: The ability to adjust yarn properties—such as luster, twist level, or filament count—to resolve specific tufting or finishing issues on the manufacturer’s floor.

- Innovation Pipeline: Partners who invest in R&D bring next-generation solutions, such as enhanced soil-blocking polymer additives or fibers with improved compression recovery, to their clients first.

- Supply Chain Reliability: Consistent quality and on-time delivery are paramount. This is where a supplier’s commitment to modern, automated production and stringent quality control, like the rigorous standards maintained by glyarn, translates directly into fewer production delays and higher first-pass yield for the carpet manufacturer.

- Market Intelligence: A good supplier provides insights into emerging trends, regulatory changes, and new application opportunities, helping manufacturers stay ahead of the curve.

7. Conclusion: Building Superior Carpets from the Yarn Up

The choice of yarn is the most consequential decision in carpet manufacturing. It is a complex interplay of polymer science, engineering, and market strategy. By moving beyond generic fiber labels to a nuanced understanding of yarn construction, finishes, and performance data, manufacturers and specifiers can make precise, defensible choices that optimize for durability, aesthetics, and cost.

Ultimately, success lies in building products with integrity from the ground up. This requires partnering with yarn suppliers who are not just sources of material, but true collaborators in innovation and quality. Whether developing a high-performance contract carpet or a luxurious residential product, the journey to market leadership begins with a single, well-chosen thread.